Resources

Application Note

- Enhancing Monitoring in Marine Propulsion Control Systems

- Rugged Panel PC Solution for Heavy-duty Electric Trucks Charging Depots

Engineered for demanding environments, Moxa’s industrial-grade panel PCs are ideal for HMI applications. No matter the environment, these panel PCs deliver durability and efficiency.

Engineered to meet international industry standards, Moxa's panel PCs ensure dependable performance in harsh environments.

Built for extreme conditions, Moxa’s panel PCs ensure long-term reliability against temperature fluctuations, dust, and moisture.

Panel PC for Rail

Panel PC for Tough Environments

Target Application

High Performance Explosion-proof Panel PC

Target Application

Moxa’s rugged panel PCs perform reliably in the most demanding industrial environments. Their industrial-grade durability, wide-temperature operation, and glove-friendly multi-touch screens enable seamless control and monitoring, even in harsh conditions.

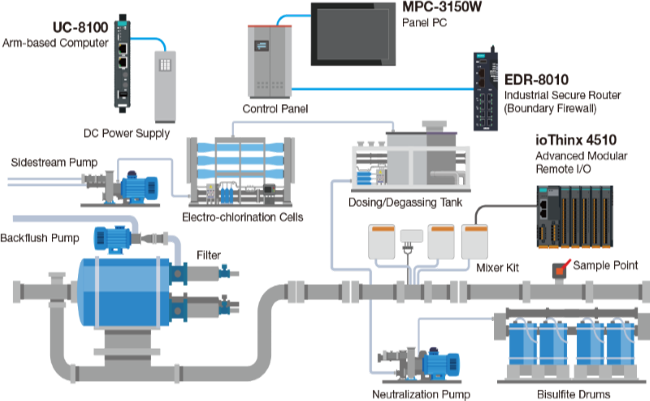

To comply with ballast water treatment regulations, specific system requirements must be met. A panel PC plays a crucial role in ensuring seamless integration by offering a centralized interface for monitoring and control. These systems must also withstand harsh marine environments, maintaining consistent performance and regulatory compliance. A panel PC’s rugged design, combined with its ability to handle critical data and display operational insights, makes it an essential component for successful ballast water treatment system implementation.

System Requirements

Why Moxa

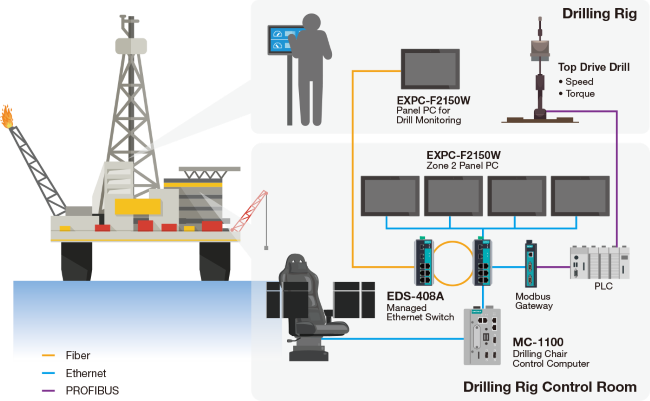

Drilling control systems are at the heart of modern oil-and-gas operations, providing real-time visualization and management of critical drilling processes. These systems enable operators to monitor and control field activities with precision, even in the most challenging environments. To ensure reliability, these systems require rugged computing solutions that meet stringent industry standards and perform consistently in harsh drilling conditions.

System Requirements

Why Moxa

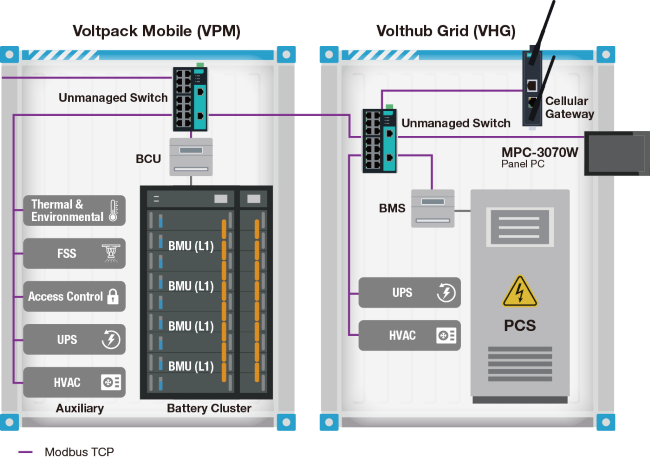

Battery Energy Storage Systems (BESS) are pivotal in transforming global energy networks, enabling the efficient integration of renewable energy sources. In this context, panel PCs are essential for ensuring the seamless operation of BESS containers. These devices provide centralized monitoring and control capabilities, enabling real-time data visualization. By leveraging advanced panel PCs and industrial-grade solutions, operators can ensure the long-term reliability of BESS containers, driving the transition to sustainable energy networks.

System Requirements

Why Moxa

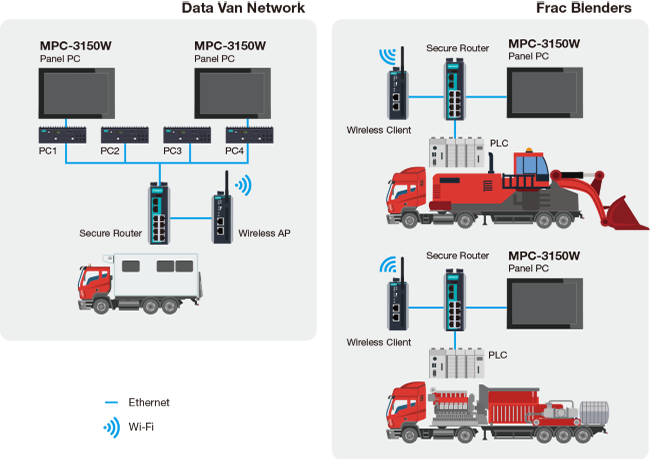

During hydraulic fracturing, frac blenders and data vans are crucial for operational efficiency and accuracy. These critical operations require robust and reliable computing and networking solutions to withstand harsh environments. Moxa’s panel PCs and networking devices provide reliable performance and seamless connectivity for frac blender operations and data van networks in demanding environments.

System Requirements

Why Moxa

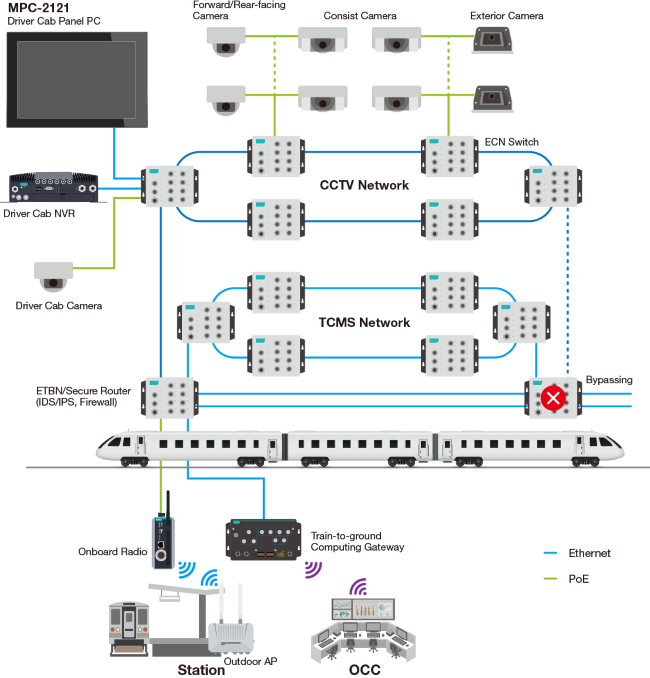

Secure and reliable onboard surveillance is essential for modern train operations, ensuring the safety of passengers and the integrity of critical data. Comprehensive systems that integrate IP cameras, versatile computers, and high-speed wired or wireless networking solutions play a pivotal role in enabling live viewing and recording for CCTV and passenger information systems (PIS). A vital component of such systems is the Train Operator Display (TOD) panel PC. This device serves as a shared display for PIS and CCTV, optimizing space in the driver’s cab while providing real-time monitoring and control.

System Requirements

Why Moxa

Industrial Panel PCs |

MPC-2000 Series

|

MPC-3000 Series |

EXPC-F2000W Series |

|||||

| Product Series | MPC-2101 | MPC-2121 | MPC-3070W | MPC-3100 | MPC-3120 MPC-3120W |

MPC-3150 MPC-3150W |

EXPC-F2120W | EXPC-F2150W |

| Panel Size | 10.4 in | 12 in | 7 in | 10.4 in | 12.1 in (4:3) 12.1 in (16:10) |

15 in (4:3) 15.6 in (16:9) |

12.1 in (16:10) | 15.6 in (16:9) |

| CPU | Intel Atom® E3845 | Intel Atom® Quad-core x6425E Dual-core x6211E |

Intel® Core™ - i7-1185G7E - i5-1145G7E Intel® Celeron® 6305E |

Intel® Core™ - i7-1185G7E - i5-1145G7E - i3-1115G4E |

||||

| Ethernet Ports | 2 x Auto-sensing 10/100 Mbps ports (M12 D-coded 4P connector) |

2 x Auto-sensing 10/100/1000 Mbps ports (RJ45 connector) | 4 x Auto-sensing 10/100/1000 Mbps ports (RJ45 connector) | |||||

| Serial Ports | 1 x RS-232/422/485 port (M12 A-coded 12P connector) | 2 x RS-232/422/485 ports (software-selectable, DB9 male connector) | 3 x RS-232/422/485 ports (software-selectable, DB9 male connector) | |||||

| USB | 1 x USB 2.0 host (M12 A-coded 5P connector) | 2 x USB 3.0 hosts (type-A connector) | 2 x USB 3.0 hosts (type-A connector) | |||||

| Light Intensity (Brightness) | 500/1000 nits | 400/1000 nits | 1200 nits | |||||

| Touch Type | Projective capacitive (PCAP) touchscreen | Projective capacitive (PCAP)

touchscreen GGG sensor with optical bonding |

||||||

| Input Voltage | 24 to 110 VDC | 12/24 VDC | DC models: 9 to 36 VDC AC models: 100 to 240 VAC |

|||||

| IP Rating | IP66 | IP66 (front), IP20 (rear) | IP66 (front), IP42 (rear; with all IOs plugged in) | |||||

| Operating Temperature | -40 to 70°C (-40 to 158°F) | -30 to 60°C (-22 to 140°F) | -40 to 70°C (-40 to 158°F) | |||||

| Standards and Certifications | EN 50155 | CID2, ATEX Zone 2, IECEx Zone 2, DNV | C1D2/C2D2, ATEX Zone 2, and IECEx Zone2/Zone 22 | |||||