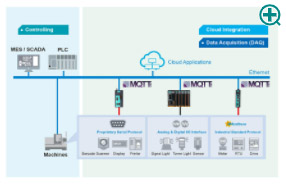

Capture OT Data I Work with OT Data I Move OT Data I Secure OT Data

Data Acquisition — The OT Data You Need At Your Fingertips

We all know that large amounts of data are readily available in operational sites. However, throughout our 30 years of experience in helping customers connect to their OT data, two challenges have consistently made data acquisition difficult.

-

Is Production Inefficiency Caused by

Poor Data Acquisition Methods?In the past, controllers (such as PLC and DCS) received data from operating devices for mostly monitoring and control purposes, so engineers regarded controllers as the best option to retrieve the required OT data. However, requiring controllers to provide additional data continuously will eventually affect the efficiency of the initial control function. Learn how our remote I/Os or industrial communication can resolve your problems.

Silos Everywhere — Can We Break Free

From This OT Data Deadlock?OT systems are typically used for long periods, so it is common that equipment from a variety of vendors functions in the same system. Moreover, each equipment has its own proprietary communication protocol. Therefore, data silos have formed over time. When seeking to aggregate data from different systems, proprietary protocols make integration difficult. Learn how our industrial protocol gateways, including BACnet gateways, offer you a solution.

Data Preparation — Seamlessly Integrating With IT Systems

The success of industrial digital transformation lies in the smooth flow of data between OT and IT systems. Therefore, if OT data can be converted into usable data for IT systems, more effective real-time display, analysis, and feedback can be achieved. First, two common challenges need to be overcome.

-

On Point for OT;

A Mystery for ITIn Industrial DX, IT cannot analyze OT data directly without context. For example, the value read from a 16-bit temperature sensor is 10,000. What needs to be added to this value is the temperature unit to indicate whether it’s Celsius or Fahrenheit, as well as the time of occurrence. Moreover, continuously transmitting the same data to the cloud is not cost-efficient. Learn how our IIoT gateway can resolve your problems.

How Can We Achieve True Intelligence

With Such Slow Reaction Time?The beauty of Industrial DX is in analyzing OT data and receiving real-time feedback to optimize operating equipment. But if all decisions must wait for analysis, the response time may be too slow to meet the real-time requirements of OT. Therefore, the current approach is to train AI models through cloud computing and deploy the trained AI models on edge computers to perform inference and/or prediction, based on the application’s requirements.

Data Transmission — Avoid Incomplete OT Data

To avoid receiving incomplete data that leads to poor data analysis, a reliable OT data network is the key to your success. Let’s take a closer look at two common challenges that make data completeness difficult to achieve.

-

Heat Waves Are Not Only Terrible For You

But Also For Your DataSince OT environments are not normally as stable as IT environments, data transmissions will inevitably be affected by environmental issues, such as extreme temperatures or electromagnetic waves generated when starting a device, causing network interruptions and incomplete data. Therefore, strengthening network resilience needs serious consideration.

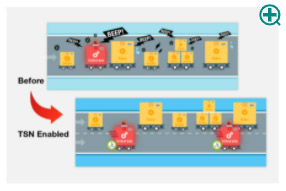

Is Your OT Data Always

At the Wrong Place

At The Wrong Time?To meet the requirements of Industrial DX, more diverse and real-time data is needed. Inevitably, this will significantly increase the amount of OT data that needs to be transmitted. Furthermore, high-definition images have gradually become an important source. Therefore, keeping the control data as the first priority to continue operations becomes crucial. Learn how time-sensitive networking (TSN) can resolve your problems.

Data Security — Avoid OT Data

Vulnerability

To analyze OT data in real time, we connect more and more OT devices to the Internet. However, all these new connections may cause vulnerabilities in the network, allowing unauthorized access to the network.

-

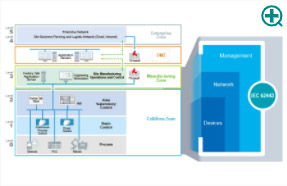

When OT Data Is Out,

It’s Easy to Bring Viruses HomeIn the past, OT systems did not need to be connected to the Internet, so physical protection alone was good enough. However, to get OT data in real time, we connect more and more OT devices to the Internet, exposing enterprises to hackers and computer viruses. Therefore, the concept of "defense in depth" has become very important.

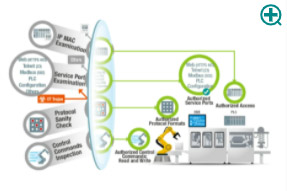

When OT Data Is Too Transparent,

It’s Easy to Get HurtMost of the communication protocols commonly used in OT are not originally designed with encryptions or authentications. What’s more, IT management tools cannot recognize OT communication protocols, so unauthorized commands may enter the network. This way, anyone who accesses the OT network can issue commands to control the operation of all devices on the network, involving unpredictable risks. Therefore, you can consider strengthening your industrial cybersecurity.