Facilitating IIoT Big Data for Semiconductor Industries

2016-04-19

| Location / Country |

Taiwan |

| Product Solutions |

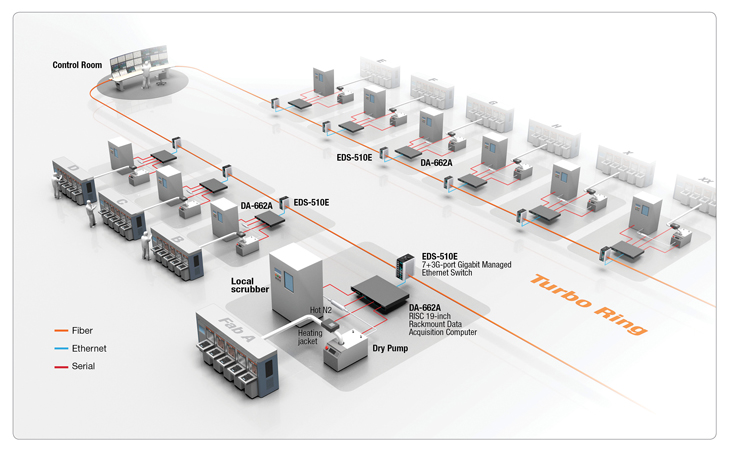

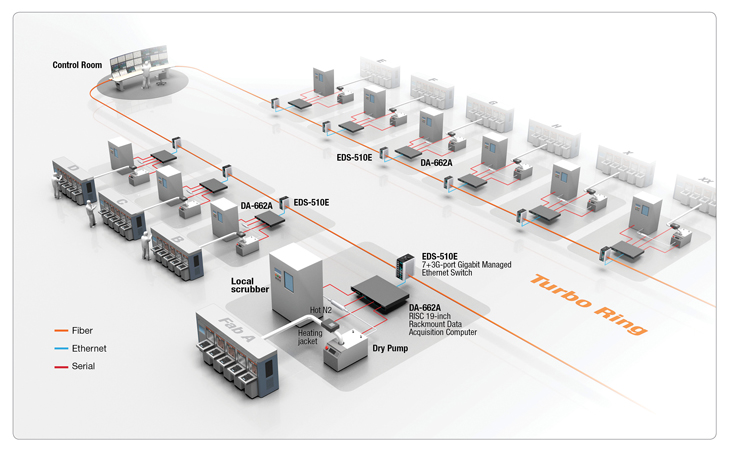

DA-662A

RISC 19-inch rackmount data acquisition computers with 8 to 16 serial ports, 4 Ethernet ports, USB

EDS-510E Series

7+3G-port Gigabit managed Ethernet switches |

|

Project Introduction

With the Industrial Internet of Things (Industrial IoT) trend, semiconductor manufacturers have started adding big data acquisition and analysis into their centralized automation management systems in order to improve production efficiency. Moxa’s reliable networking infrastructure has enabled one system integrator, ArchCyber Technology, to build a real-time dry pump monitoring system that optimizes efficiency and reduces total production costs by at least US$30 million per year.

ArchCyber has partnered with Moxa in providing a solution for real-time dry pump monitoring systems with customized functions for leading semiconductor manufacturers. Dry pump systems, although not the main production devices, play an important role in the yield rate and production cost of semiconductor manufacturing. Before the dry pump monitoring system was installed, the customer was unable to predict the device status and could only perform regular maintenance to avoid unexpected abnormality. Now, the semiconductor manufacturer can analyze the health of the dry pumps, and predict when to replace the device, not only reducing maintenance efforts, but also saving product costs.

System Requirements

- Protocol conversion among different dry pump devices

- Reliable network performance against harsh environment, such as electrical interference

- Real-time dry pump data acquisition, storage, and management for predictive system maintenance and maximized system downtime

Moxa Solution

Typically, there are about two thousand dry pump units in a 12-inch Wafer Fab. When monitoring and analyzing such a huge amount of data, it is essential to ensure a high-performance network for data communications. ArchCyber deploys Moxa’s EDS-510E gigabit managed switches to form a fiber ring topology, that can serve sufficient bandwidth as well as endure electronics disturbances in the manufacturing environment.

In addition, different brands of dry pumps support different protocols. Therefore, the customer needs to convert the various proprietary protocols of the different dry pump systems to collect and transmit the data. Moxa’s DA-662A embedded computers, which support ample and diversified interfaces, are installed to perform the protocol conversion.

Check out Moxa's IIoT network infrastructure solutions. Or download the FAQ to see if your network is IIoT-ready.

Why Moxa

- Industrial-grade ruggedness, such as fan-less design

- Moxa Turbo Ring redundancy protocol for millisecond recovery

- Embedded computer supports protocol conversion

“As the trend of Industrial IoT continues to become increasingly important, more devices will be converged on one network, and the network will demand a centralized management system to acquire, store, and analyze the big data, in order for organizations to receive accurate information and make decisions. We rely heavily on Moxa’s network infrastructure to realize the IIoT applications.” said Ray Huang, GM of ArchCyber Technology. “As the trend of Industrial IoT continues to become increasingly important, more devices will be converged on one network, and the network will demand a centralized management system to acquire, store, and analyze the big data, in order for organizations to receive accurate information and make decisions. We rely heavily on Moxa’s network infrastructure to realize the IIoT applications.” said Ray Huang, GM of ArchCyber Technology.

|

“As the trend of Industrial IoT continues to become increasingly important, more devices will be converged on one network, and the network will demand a centralized management system to acquire, store, and analyze the big data, in order for organizations to receive accurate information and make decisions. We rely heavily on Moxa’s network infrastructure to realize the IIoT applications.” said Ray Huang, GM of

“As the trend of Industrial IoT continues to become increasingly important, more devices will be converged on one network, and the network will demand a centralized management system to acquire, store, and analyze the big data, in order for organizations to receive accurate information and make decisions. We rely heavily on Moxa’s network infrastructure to realize the IIoT applications.” said Ray Huang, GM of