Resources / Case Studies

Extending Network Communication in Ever-Changing Underground Mines

| Application | Underground Mining Communication |

|---|---|

| Industry | Other |

| Region | Europe |

Introduction

Mining operations are extremely hazardous and take place in unpredictable environments. In fact, mining operations are always in a state of change, with frequent expansions and changes to the drilling site and internal passageways.

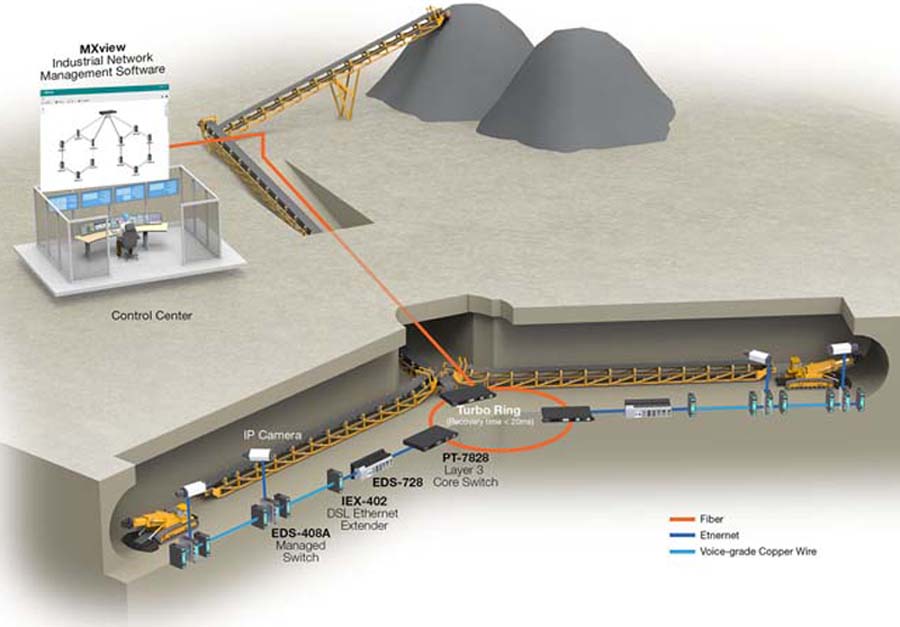

A leading mine operator in eastern Europe decided to implement a reliable remote IP-based communication networking system for control and monitoring. The system is intended to ensure that the mine’s controller/sensor system is reliable and productive, and that the CCTV system is real-time. One of the main interests is protecting the safety of miners working in such a harsh and dangerous environment. However, as the numbers of drilling sites and internal passageways increase, more and more sensors, I/O points, and cameras need to be deployed, and consequently more networking devices and network ports need to be added, and the bandwidth of the backbone network needs to be increased.

Remote sensors, I/O points, and cameras need to be able to communicate over the network, and since the distance between devices could be hundreds of meters, or even several kilometers, you might think that fiber optic cabling is appropriate for this application. However, temperatures in the mine could get so high as to damage or even melt the fiber optic cabling, and generally speaking, the curvature of many of the tunnels is so high that it’s not practical to deploy fiber. Moreover, a remote industrial network management system that gives mining operators the ability to monitor the network’s operational status and react in an instant is needed to increase productivity and reduce the amount of time that network engineers need to spend onsite at dangerous drilling sites to check network issues. You should also be aware that because of the need for cross-site communications, layer 3 networking devices must be used.

System Requirements

- Transmit control traffic signals and video transmission over distances up to 1 km

- Use existing copper wiring underground for IP networking and high resilience and adaptability for network expansion and changes

- Fanless installation Layer 3 switches with high port density for harsh environment and distributed networks

- Easy installation, diagnosis, and management

Moxa Solution

Moxa provides industrial grade, managed DSL extenders to enable long-distance (300 meters to 3 kilometers for VDSL2 type of extenders, and up to 8 km with G.SHDSL type of extenders for point-to-point communications) Ethernet-based connections for remote sensors, I/O points, and even HD CCTV cameras that use a daisy-chain topology with the mine’s existing copper cabling. With this kind of solution, mining operators can easily use existing wiring to expand and change their network design along with the transition of their drilling sites and paths. The entire system was constructed and connected together using a layer 3 backbone network in which the devices are all wide-temperature and fanless to ensure reliable operating in a harsh underground environment. In addition, a real-time centralized network management system was deployed to give mining operators the ability to monitor the entire system remotely, so they can determine the status of the network instantly.

Why Moxa

- Uses existing copper wiring for point-to-point Ethernet connections over DSL technology

- Can support Ethernet over distances up to 3 km for VDSL2 and 8 km for G.SHDSL with data rates up to 100 Mbps and 15.3 Mbps

- Auto CO/CPE negotiation on DSL extenders for easy plug-and-play installation

- Full range of connection strength LED indicators on DSL extenders for simple onsite troubleshooting

- Fanless industrial grade design for operation in harsh environments increases system availability and reduces maintenance costs

- MXview with a device visualization interface for easy remote management

- 5-year warranty